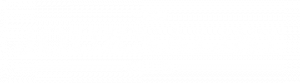

BoI attracted seven giant Chinese car companies to show their plan for purchasing parts domestically to draw Thai manufacturers into the global supply chain.

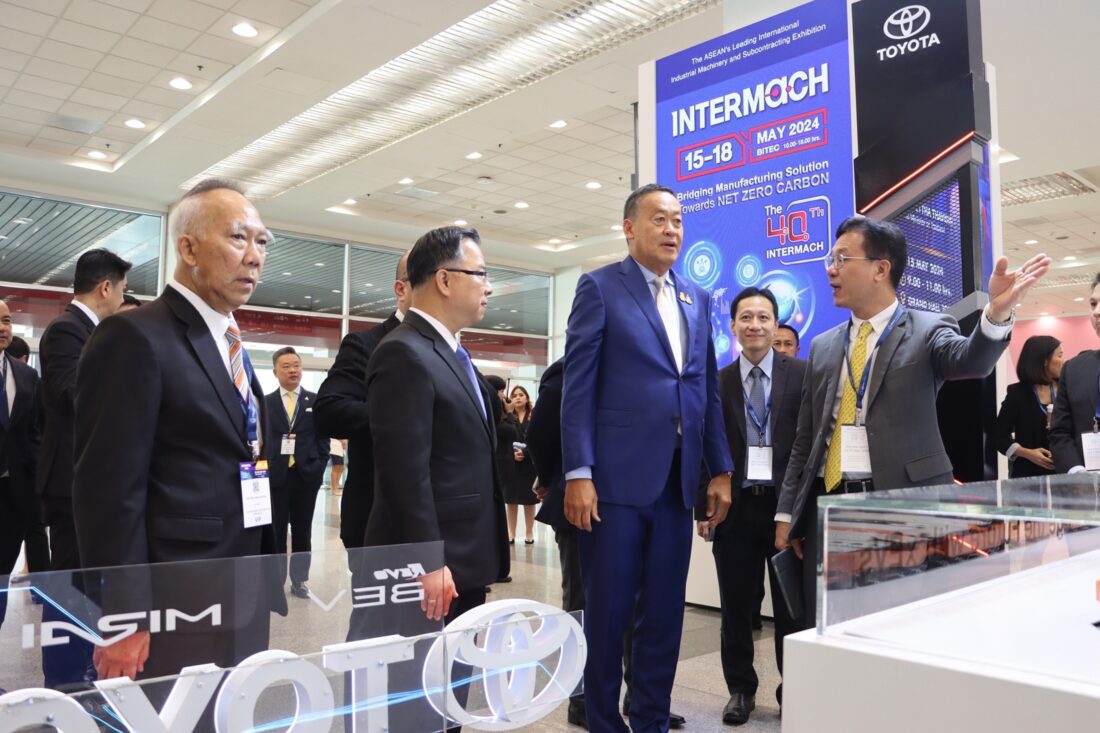

Secretary general of the Board of Investment (BoI), Narit Therdsteerasukdi revealed that organizing an event showing international industrial parts “ SUBCON Thailand 2024” between May 15-18, 2024. BOI has organized special activities. “ BoI Symposium: EV Supply Chain”

BoI attract seven car companies from China to show the parts procurement plan in the country. The activity is aimed to assist Thai entrepreneurs to enter the global electric vehicle supply chain.

He said there are opportunities to enhance the growth of using domestic parts up to 90%. The event will support Thailand to become a hub in ASEAN

and support Thailand to become a production base for export to the world market in the long term.

Seven companies to show procurement plan

“The event was the first time in Thailand that seven leading car manufacturers from China’s namely BYD, MG, Great Wall Motor, NETA, Changan, GAC Aion and Omoda & Jaecoo have come to share their vision of developing electric vehicle industry. They also showed their procurement plan to purchase parts from the domestic market.

Thailand is ready to assist Thai entrepreneurs to involve the world supply chain. Domestic manufacturers registered to participate domestic parts purchasing plan more than 1,500 participants.

Currently, car manufacturers from China that manufactured EVs in Thailand,

namely GWM. NETA and MG while BYD and GAC Aion planned to start production in the 3-4 quarter this year. The others are Changan which will begin production at the beginning of the year 2025. The manufacturing will help to gradually increase demand for domestic parts.

“The opening of this seminar. Will be an important occasion. domestic part manufacturers will acknowledge the direction of electric vehicle development

and plans for purchasing parts directly from executives. The event can create opportunities for business matching

and upgrade supply chain of electric vehicle industry to strengthen leadership in Thailand. well as the strengthening Thailand to become an important production base of the global in the future. ” Mr Narit said.

BOI provided comprehensive benefits for electric vehicle manufacturing

in every segment well as 17 important parts eligible the highest privileges including battery and charging station.

During the past 2- 3 years. BoI promoted EVs industry in Thailand with total investment over 80 billion baht. There are 18 projects to manufacture electric vehicles with battery ( BEV) with approximate investment 40 billion baht. Total production capacity of electric cars 400,000 units

China automakers’ plan to develop EVs production base

The seminar on “ BOI Symposium: EV Supply Chain”, the seven leading Chinese automobile manufacturers namely BYD, MG, Great Wall Motor, NETA, Changan, GAC Aion and Omoda & Jaecoo share their vision. They also share procurement plan for domestic parts. The plan will enhance the opportunity to use domestic parts up to 100% 90 which support Thailand to become a production base for export in the future.

Mr Ma Haiyang , general manager of International Business of GAC AION New Energy Automobile or GAC AION said the company Committed to developing the chain Production in Thailand provides Strong and want Thailand to be the center middle of ASEAN which will have investment in the production plant including distribution in Thailand and abroad We will cooperate with parts manufacturers. in the country to develop high quality products that meet The needs of the administrators Consumers in Thailand and the ASEAN region

Mr Yu Bin Ke general manager of BYD Auto (Thailand) Co., said BYD is the top-selling new energy vehicle manufacturer of the world in 2023 and. As of March, the company has accumulated sales worldwide more than 7 million units.

Currently. The BYD factory is preparing to use more than 40% of domestic parts from domestic parts manufacturers. The company is a plan to increase purchasing every year. In the future, the company will upgrade production and development domestic parts to be ” Made in Thailand”.

Mr Shen Shen Xinghua, chairman of the Changan Auto Sales ( Thailand ) Co revealed that Changan has important goals in reducing carbon dioxide emissions. The company plans to invest US$10 billion to manufacture produce newer energy vehicles 1.5 million cars.

The companywants Thailand is the hub of ASEAN both production and selling, including research and development worth approximately 10,000 million baht.

“It is expected that car production will begin in the first quarter of the year 2025 with production capacity of 100,000 units. Using local parts up to 60% and there is a chance to meet 90% from Thai government support measures.”

Related News : BoI approves BBGI Firmbox Bio